Few things can transform your backyard into a paradise like a beautifully designed and expertly crafted pool. Building a pool isn’t just about having a place to cool off; it’s about creating a focal point for relaxation, entertainment, and cherished memories. Whether you’re envisioning a serene retreat or a lively hub for gatherings, this comprehensive guide will steer you through the journey of bringing your dream pool from Vietnam natural stone to life.

Swimming Pool Construction – What Are Your Concerns?

Are you interested in building a family pool or a commercial swimming pool? But you don’t know where to start? Surely, when customers decide to undertake a swimming pool construction project, they have many doubts. So, what are the things you should be concerned about?

- Are you looking for a Vietnam stone supplier?

- What is the most accurate construction process?

- What should you prepare for during construction?

- Do you need detailed construction methods and measures to make the right and most accurate choices?

- Do you need the most detailed swimming pool construction drawing?

- What will be the construction cost of the project?

- Have you chosen a quality construction company?

- Do you know that choosing a low-quality swimming pool construction company will lead to rapid deterioration of the project and equipment failure?

- How can you save on construction costs? What equipment do you need when building the project?

These are undoubtedly the concerns that any customer has when planning a swimming pool construction project. So, let Nam Stone help you solve all these doubts and questions. Call us: +61 422 124 969 to receive direct advice from our team of experts.

What are the steps in the swimming pool construction process?

To carry out the construction and complete the project, you need to pay special attention to the construction process. What steps are included? How should they be carried out? Below are the 7 essential phases.

Step 1: On site survey

For a professional swimming pool construction process, the first step that contractors need to undertake is site survey. This will help you accurately verify the current information to determine the following issues:

- Detailed characteristics of the site: Whether it is flat or uneven.

- Surroundings and context of the construction area.

- Construction area measurement.

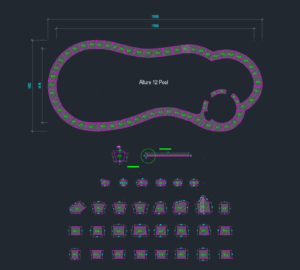

Step 2: Creating Drawings and Formulating the Construction Plan

Whether it’s a small or large project, absolute precision is essential. Therefore, a set of drawings is a necessary element. It helps the project owner and clients to closely follow all details, ensuring that the construction progresses according to the designated timeline.

Step 3: Obtaining Building Permits

This is a crucial step when constructing a swimming pool, especially for commercial pools. Therefore, it’s necessary to promptly register with the relevant authorities after conducting the site survey and having the pool design drawings. Only then can business operations proceed smoothly without legal complications.

Step 4: Executing the Pool Construction

After successfully obtaining the construction permits, it’s time to proceed with the construction process. This process unfolds in specific stages as follows:

Phase 1: Finding a Reputable Construction Company

In the current market, there are numerous construction firms available. However, not all of them provide quality services to consumers. Meanwhile, the construction company is considered one of the crucial factors that directly affect the quality of the project upon completion.

To find a reputable company, you can follow these methods:

- Contact relatives, friends, or individuals who have previously built a pool and ask for their opinions.

- Join construction-related forums or groups to seek recommendations for trustworthy construction companies.

- Search for construction companies on Google. Generally, well-regarded companies with a high number of searches and positive reviews will rank highly on Google. This could be a good basis for consideration.

- Once you’ve identified a construction company, visit their website, social media pages, and other platforms to review feedback from previous customers who have used their services.”

Phase 2: Excavation Process

This phase involves shaping the structure. Based on the previously designed drawings, the construction team will use chalk or specialized paint to outline the shape and size of the project in the intended construction area. This ensures accuracy according to the design drawings.

The completion time of this phase depends on the scale and size of the project, ranging from a few hours to several days.

Phase 3: Pouring the Pool Floor Foundation

Pouring the floor foundation is done by spreading stone directly onto the bottom of the project with a thickness of 10 to 20 cm. The estimated completion time for this foundation work is about 1 day.

However, to enhance the load-bearing capacity of the structure and increase the tensile strength of the concrete, formwork needs to be installed. This phase takes around 1-2 days to complete, with steel reinforcements evenly placed. Steel bands are crisscrossed and spaced alternately, wrapped within the concrete shell.

Following the completion of this step, the installation of the bottom drainage equipment or drainage pipes for the project will take place.

Phase 4: Pouring the Pool Walls

After the foundation phase, it’s time for pouring the pool walls. This step is also carried out in accordance with technical requirements, ensuring proper hardness, stability, and preventing cement from losing its water content.

Depending on each project, different materials will be used for pouring the walls. However, in general, bricks are used as formwork for the outside of the pool. For the interior, plywood is used for family pools, while reinforced formwork is used for larger-scale projects.

Currently, plywood formwork with a film coating is increasingly popular due to its advantages of being lightweight, easy to assemble and disassemble, and simple to store.”

Phase 5: Plumbing and Equipment Installation

During this phase of swimming pool construction, we will proceed with the installation of the plumbing system and pool equipment. Here are the specific steps:

After pouring the concrete pool bottom, install the necessary pipes through the pool walls, such as the suction and return pipes, electrical conduit for lighting, etc. The positioning of these components from the water surface downwards is calculated and determined by technical staff to ensure optimal functionality.

Once the pool walls are poured and the formwork is removed, it’s time to connect all the equipment from the exterior of the pool to the equipment room. When proceeding with this step, consider the following:

- Ensure the stability of support and brackets for the pipes around the construction. When backfilling is done to complete the pool floor, pay attention to the areas surrounding the pool.

- Ensure that these areas are filled with gravel around pipe locations. Avoid using soil as it can be highly adhesive and may cause pipes to break. Install ladders, pull electrical wires, and perform other necessary tasks.

This phase will be carried out after the pool has been tiled, and the equipment room has been constructed. The specific tasks include:

- Pulling electrical wires from the equipment room to the project’s lights.

- Installing ladders, lights, and decorative equipment if applicable.

- Installing equipment such as filtration pumps, filter columns, chemical disinfection systems, etc., in the equipment room.

Phase 6: Waterproofing the Pool Surface

Waterproofing is a crucial step that construction companies must carefully calculate and consider. If not done correctly, this process can lead to water leakage from the pool, resulting in wastage. Additionally, it could allow untreated water from the outside to seep into the pool, directly affecting water quality.

To waterproof the structure, construction companies usually follow these steps:

- Clean the surface of the project.

- Then, use waterproofing additives and Sika Latex mixed with cement or cement mortar and sand to enhance the waterproofing capacity of the structure.

- The estimated completion time for this phase is around 1 to 3 days.

Phase 7: Tiling the Pool Bottom, Walls, and Surrounding Areas

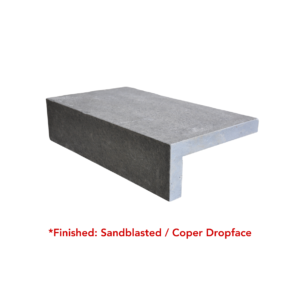

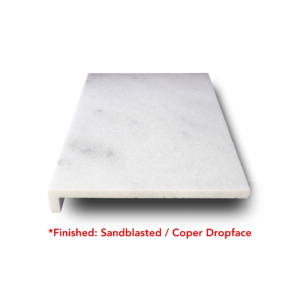

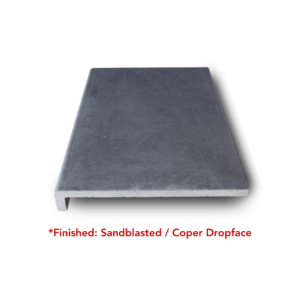

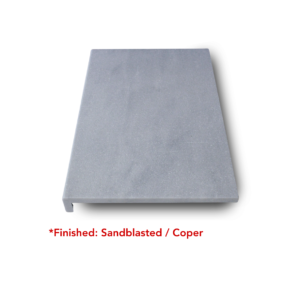

Vietnam natural stone serves not only to enhance the aesthetic appeal of the project but also to prevent slips and falls. Many types of stone materials nowadays possess anti-slip properties, which significantly reduce the risk of accidents for swimmers. Furthermore, certain Vietnam natural stone materials, such as mosaic tiles, copers can also contribute to increased waterproofing capabilities. Therefore, you can consider various options when choosing tiling materials.

Additionally, when selecting tiling materials, you can also create special patterns on the pool floor, such as dolphins or company logos.

Phase 8: Landscaping and Pool Area Enhancement

Depending on the purpose of the project and the available land, we can design additional amenities around the pool, such as pergolas, sunshades, flower pots, changing rooms, restrooms, and more. At this point, the construction process can be considered complete. However, before putting the project into operation, a trial run is necessary to evaluate the quality of the completed structure.

Step 6: Find your trusted stone supplier

At Nam Stone, we take pride in our ability to create intricate and sophisticated pools that stand as a testament to our expertise. Our dedicated and skillful team is well-equipped to handle the challenges that come with designing and constructing complex pool projects. Whether it’s incorporating unique features, intricate tiling patterns, or advanced water circulation systems, our team has the experience and technical know-how to bring even the most intricate pool visions to life. With a proven track record of successful projects, we are confident in our capacity to turn your ambitious ideas into stunning aquatic realities. Here are some Vietnam natural stone materials that might be suitable for your next projects.

Warm Endnote

Building a pool is a journey that combines creativity, engineering precision, and the expertise of a skilled team. From the initial concept to the final landscaping touches, every step plays a vital role in crafting your aquatic oasis. Remember, a well-constructed pool is not just a water-filled space but a sanctuary of leisure, a hub of enjoyment, and a canvas for unforgettable memories and choose right Vietnam natural stone material that suitable for your project.